A Science-Backed Solution to Maintaining Optimal Plant Parts Stock Levels

A client approached GTC Control Solutions with a unique request related to their industrial control systems. They asked us:

We all knew about the Level I, II and III supply chain spares that the OEM recommends, but this customer wanted a little more to justify the investment in spares, so we delivered. Our solution involved a scientifically grounded approach to determine the optimal stock levels for spares in their control systems, ensuring a high reliability and minimal downtime due to forced outages.

Just from being in business since 2001, we had a very good idea about which were the most sold or repaired components. Fortunately, we also collected all these thousands of datapoints: we have records for every component ever sold or repaired by GTC.

Our experience in emergency outage solutions and OEM spares optimization provided us with a wealth of data. We had recorded every component sold or repaired, leading to a rich dataset representing an industry average for the control systems we specialize in.

The Critical Role of Data Analysis in Determining Necessary Control System Components

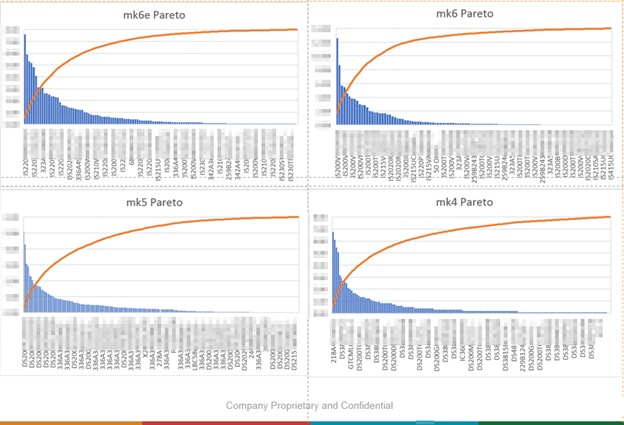

By analyzing this data, we applied Pareto Analysis to assess component failure rates and recommend the most crucial spare parts. This method has proven invaluable in inventory management for control systems, allowing our clients to focus on maintaining essential components in stock.

Our results showed a Poisson distribution pattern, highlighting the top 20 to 30 components crucial for maintaining control system reliability. This approach is particularly beneficial for multi-unit sites in remote locations, where maintaining an adequate inventory of spare parts is critical for reducing downtime in control systems.

4 Most Common Ways Industrial Plants Buy Components

Then, we considered that customers buy components in four different ways:

- Inventory Replenishment

- Emergency / Forced Outage

- Inventory Expansion through Budget Allocation

- Inventory Expansion through Unused Budget (use it or lose it!)

In every case, the purchase of parts is rational, typically limited to a minimum, and based on site experience. The repair is, in most cases, a mutually exclusive alternative to the purchase. Also, our population sample spans 23+ years, hundreds of panels and thousands of components.

What does this all mean? In very simple terms, our data represents a very good industry average for the control systems under study.

Therefore, it was just a matter of some basic spreadsheet skills to calculate the average frequency of failure for each component and then the accumulated frequency of failure.

We plotted these two quantities and obtained the graphs shown below:

By analyzing this data, we applied Pareto Analysis to assess component failure rates and recommend the most crucial spare parts. This method has proven invaluable in inventory management for control systems, allowing our clients to focus on maintaining essential components in stock.

Our results showed a Poisson distribution pattern, highlighting the top 20 to 30 components crucial for maintaining control system reliability. GTC has applied this information in recommending spares levels, prioritizing recertification of existing stocks, and forecasting future card requirements. This approach is particularly beneficial for multi-unit sites in remote locations, where maintaining an adequate inventory of spare parts is critical for reducing downtime in control systems.

At GTC, we’re committed to providing tailored recommendations for spare parts, based on our in-depth analysis of component failure rates.

Our yearly updates on spare parts lists ensure that our clients are always prepared for any scenario, effectively mitigating the risk of forced outages and ensuring seamless operation in their control systems.

Ready to enhance the reliability and efficiency of your control systems with Pareto Analysis?

Reach out to AP4’s GTC Group for help using this technique to enhance all aspects of your spare parts management. Our expert control systems team is equipped to provide you with the optimal spare parts list, ongoing maintenance plans, and on-site assistance to ensure your systems run smoothly and efficiently.

Contact us today to optimize your control system’s performance and minimize downtime risks.